PTFE plastic has been widely used in Electronic and

electrical industry, especially suitable to be insulating materials under high

frequency, high temperature and moisture situation. PTFE enameled wire is widely used to make micro electric engine,

thermocouple and control device etc. PTFE cables and wires are one of

dispensable materials in the fields of aircraft, radar, TV set, rocket etc.

Small-caliber and thin-wall PTFE tubes are

used as insulating bushes, the colorful small-caliber tubes are used as bushes of outgoing lines, heat expansion tube and screwed tube in instruments.

It is the excellent insulated protection layer of cable and thermocouple.

Middle-caliber PTFE pipes are excellent

materials of insulating bushes for dual internal water cooling generator,

stator and rotator, and electric solvent liquid level gage.

Large-caliber glassfiber-reinforced PTFE

pipes can be used as insulated materials to set rotator and stator of

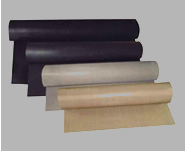

Six sodium fluoride electric generator apart. Varnished glass cloth and PTFE

glass fiber laminated sheet are insulated materials of high frequency and high

temperature.

1)PTFE

glass fiber with wide length can be used to construct domes of large-scaled open

squares because of its excellent properties of wear resistance and

climate-resistance. This kind of dome will be light-transparent with light

weight.

2)Varnished

PTFE fabric can be made into laminated sheet through cutting and

thermo-pressing multi-layers. Thin laminated sheet can be made into insolated

materials for electrician, radome, electrical component, corrosive–resistant

leaves. Thick laminated plate can be used as low-friction sliding

materials, e.g. ship-launching board.

3) To compound varnished PTFE with single-sided

or double-sided copper foil will produce copper-clad laminates (i.e. printed wire

board), which can be used under ultra high frequency and high temperature conditions.

4) Having a chemical treatment on single side of

varnished PTFE clothes firstly, and then coating adhesive on it, it will become a

convenient adhesive tape of adhesive-resistance and insulating.

5) To weave fiberglass yarn into mesh fabric,

and then have it impregnated, dried, baked and finally sintered, it will become

an adhesive-resistant mesh tape which is applied in the fields of paper-making,

foods and dyeing. Adhesive-resistant PTFE mesh fabrics can be woven into a continuously cooperating conveyor belt, which has a good effect on drying papers, foods, and

textiles etc.

-

PTFE electronic component

-

PTFE electronic component

-

Ultra-small PTFE electronic thread

-

PTFE wire

-

PTFE double-color lapping electronic thread

-

PTFE high temperature cable

-

PTFE thermocouple

-

PTFE high temperature fiberglass fabric

-

PTFE colorful electronic tube